Beginning

Forceful classification solution has arisen as a innovative approach for optimizing refuse classification effectiveness. This modality employs the principle of momentum principle to identify debris contents based on their density. By flinging rubbish into a compartment, ballistic separation can precisely discriminate various fractions of materials, like plastics, metals, and organics. This optimized method to waste processing can drastically boost recycling rates and decrease landfill extent.

Revolutionary Component Recovery: The Influence of Trajectory Classifiers

Impact profilers are advancing the area of matter recovery. These cutting-edge devices utilize high-velocity air streams to arrange contents with impressive accuracy. Unlike standard approaches, ballistic separators accurately handle a expansive range of objects, from plastics and metals to glass and organic waste. This wide applicability makes them valuable for both big recycling facilities and micro operations.

The intrinsic performance of ballistic separators enables a markedly elevated recovery rate compared to conventional techniques. Furthermore, their compact design enables for integration into existing recycling networks with negligible disruption. As the demand for sustainable procedures strives to multiply, ballistic separators are prepared to play an rapidly fundamental role in influencing a circular economy.

- Perks of Ballistic Separators:

- Enhanced recovery rates

- Optimized material separation

- Flexibility for different materials

- Diminished operational costs

- Eco-friendly impact reduction

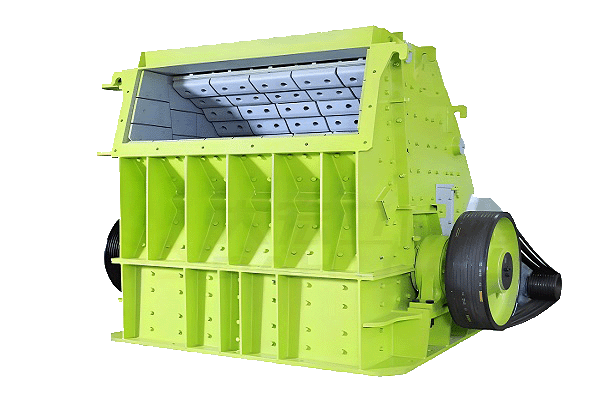

Refining Metal Extraction: High-Performance Metal Shredders in Action

The alloy extraction domain is persistently seeking novel ways to maximize efficiency and reduce ecological impact. High-performance metal shredders have emerged as a fundamental strategy, supplying unparalleled capabilities for processing extensive volumes of waste. These modern machines utilize leading technology to fragment recyclables, classifying valuable metals from residuals with exceptional accuracy.

- Likewise, high-performance metal shredders are known for their durability and endurance, ensuring consistent performance even under demanding situations.

- Consequently, these machines contribute to the sustainability of metal extraction by minimizing waste and amplifying resource utilization.

The embracement of high-performance metal shredders is reshaping the industry, spurring advancements in metal recycling and supporting a more sustainable future.

Utilizing a Ballistic Separator for Streamlined Recycling

Evolution in recycling process are crucial to diminish the environment harm of waste. A cutting-edge answer gaining traction is the ballistic separator. This instrument employs centrifugal force to competently sort recyclable components based on their magnitude. By categorizing materials into distinct streams, the ballistic separator boosts the recycling procedure, leading to augmented recovery rates and a enhanced range of recyclable products. This development holds immense power for enhancing recycling practices and supporting a environment protection future.

AI-Powered Waste Sorting: Integrating Ballistic Separators and AI

The realm of waste management is rapidly evolving, driven by the growing need to cut environmental impact. Cutting-edge technologies are being applied to streamline recycling workflows and establish a more sustainable future. One such development is intelligent waste sorting, which employs the power of ballistic separators and artificial intelligence (AI) to segregate waste substances with unprecedented precision.

Ballistic separators behave by using high-speed gusts to hurl different classes of waste based on their size, shape, and density. This preliminary stage of separation lowers the complexity of the sorting process for AI algorithms.

State-of-the-art AI models can then understand images and data from sensors to discern specific materials with exceptional accuracy. This integration of ballistic separation and AI enables a notably efficient and computerized waste sorting system.

Refining Waste Management: A Comprehensive Guide to Waste Sorting Machines

Waste sorting is a essential step in proper waste management. Manual sorting can be prolonged and problematic, leading to contamination and increased costs. To address these challenges, sophisticated waste sorting machines have emerged as a powerful solution. These machines exploit state-of-the-art technology to rapidly sort various waste materials into designated categories.

There are countless types of waste sorting machines available, each designed for particular applications. Some common types include infrared sorters, which rely on light to differentiate different materials. Additionally, robotic arms and conveyor belts can be fitted to process waste with exactness. By mechanizing the sorting process, these machines markedly improve efficiency and reduce manual labor requirements.

- Assets of using waste sorting machines include:

- Increased efficiency in sorting waste materials

- Lowered labor costs and personnel effort

- Improved accuracy in separating recyclable materials from non-recyclable waste

- Decrease of contamination in recycling streams, leading to enhanced quality recycled products

- Nature-conscious benefits through raised recycling rates and reduced landfill waste

The Transformation of Recycling

Established recycling operations have long been the common practice for arranging and processing recyclable components. These processes often rely on manual separation by humans, which can be laborious and prone to failures. However, recent advancements in technology have led to the emergence of advanced recycling methods, such as ballistic separation.

Ballistic separation uses the force of impact to segregate different materials based on their size, weight, and shape. This high-speed process can competently handle large volumes of mixed recyclables, reducing manual labor and improving the accuracy of sorting.

Compared to traditional methods, ballistic separation offers several virtues. It is a much more mechanized process, requiring less human intervention and minimizing the risk of contamination. Additionally, it can handle a wider variety of materials, including plastics, metals, glass, and paper. This increased efficiency and flexibility make ballistic separation a promising solution for modern recycling operations.

Evaluating A Ballistic Separator for Municipal Solid Waste

This examination reviews the integration of a ballistic separator in a community solid waste management facility. The intention of this project was to increase the competence of waste distribution. The study evaluates the working aspects of the separator, including its composition, introduction method, and arrangement practice.

Furthermore, the examination analyzes the effect of the ballistic separator on waste stream composition.

- Observations collected from the machine functioning illustrate the success of the implemented solution.

- Challenges faced during the deployment process are also considered.

Advice for future refinements based on the investigation outcomes are presented.

Boosting Material Recovery Through Shredding and Separation Processes

In the environment of waste management, optimally recovering valuable materials is paramount. Shredding and separation practices play a important role in achieving this goal. By mechanically reducing materials to smaller elements, shredding streamlines the subsequent separation stages. Advanced separation technologies, such as magnets, screens, and air classifiers, can then differentiate wide-ranging material types with high precision. This progressive approach delivers a higher rate of material recovery, decreasing landfill waste and fostering a circular economy.

Deciding on a Waste Sorting Machine: Key Considerations

Waste sorting devices are important for skillfully managing waste and promoting reutilization. When picking a waste sorting machine, it is crucial to consider several parameters to ensure it meets your specialized needs.

First, determine the type of waste you will be classifying. Different machines are built for diverse types of waste, such as plastics, paper, metals, and natural remnants. Next, evaluate the volume of waste you generate. This will affect the size of the machine you require. A higher-volume machine is necessary for high-volume waste streams.

Also, assess the space available at your site. Waste sorting machines come in assorted sizes, so ensure there is sufficient room to embed the machine and allow for seamless operation. Another important factor is the scope of automation you require. Semi-automated machines offer varying degrees of labor participation.

Finally, review the operational costs associated with different machines. Some machines may depend on more frequent checks than others.

Boosting Landfill Diversion Rates with Advanced Separation Technologies

Landfills are a critical source of environmental impact. To diminish this concern, many communities are actively searching for ways to amplify landfill diversion rates. Advanced separation technologies offer a fruitful solution by efficiently sorting recyclable goods from waste streams. These innovative technologies utilize scanners and complex algorithms to distinguish various products. This causes to a elevated recovery rate of recyclable items, due to this curtailing the amount of waste sent to landfills.

The integration of these advanced separation technologies can bring manifold advantages. At first, it saves natural resources by salvaging valuable materials. Secondly, it decreases greenhouse gas emissions associated with waste disposal and the fabrication of new materials from raw resources.

industrial waste shredders Finalizing